Our services are focused

on the highest standards

of quality, safety, care of

the environment, and good

community relations

and are directed to public

and private companies

in the mining sector.

Our services are focused on the highest standards of quality, safety, care of the environment, and good community relations and are directed to public and prívate companies in the mining sector.

We specialize in versatile,

highly mobile and lighweight

drills which can operate

successfully in any

type of project, even in

remote or mountainous areas.

We specialize in versatile, highly mobile and lighweight drills which can operate successfully in any type of project, even in remote or mountainous areas.

In Kluane Drilling Ltd.

we work together with

our clients and excellent

people to provide quality

services and to continuously

improve our organization.

Our clients and excellent team of people.

In Kluane Drilling Ltd. we work together with our clients and excellent people to provide quality services and to continuously improve our organization. Our clients and excellent team of people.

We are aware of the market

requirements and

technological challenges

facing the industry.

Our team of talented

professionals continuously

works on the innovation and

improvement of our drilling

equipment, in order to offer

versatile and highly

competitive services, ideally

suited to the individual needs

of each of our customers.

Our drills have small

footprints and are extremely

quick to move and set up.

They are characterized

by their portability and the

ease with which they can

operate in remote or

mountainous areas with

difficult access.

The drills are compact and

modular, which allows them

to be disassembled and

transported by helicopter,

truck or manually along

narrow trails.

Kluane Drilling Ltd.’s drills

perform very effectively in

comparasion with

conventional drilling

equipment in terms

of depth capacity and

production rates.

The thin wall system is used

which provides more core

sample volume due to the

arger diameter of the core

and also provides a greater

proportion of power per

cubic centimeter of

cutting surface.

We are aware of the market

requirements and

technological challenges

facing the industry.

Our team of talented

professionals continuously

works on the innovation and

improvement of our drilling

equipment, in order to offer

versatile and highly

competitive services, ideally

suited to the individual needs

of each of our customers.

Our drills have small footprints

and are extremely quick to

move and set up. They are

characterized by their

portability and the ease with

which they can operate in

remote or mountainous areas

with difficult access.

The drills are compact and

modular, which allows them

to be disassembled and

transported by helicopter,

truck or manually along

narrow trails.

Kluane Drilling Ltd.’s drills

perform very effectively in

comparision with

conventional drilling

equipment in terms of depth

capacity and production rates.

The thin wall system is used

which provides more core

sample volume due to the

arger diameter of the core and

also provides a greater

proportion of power per cubic

centimeter of cutting surface.

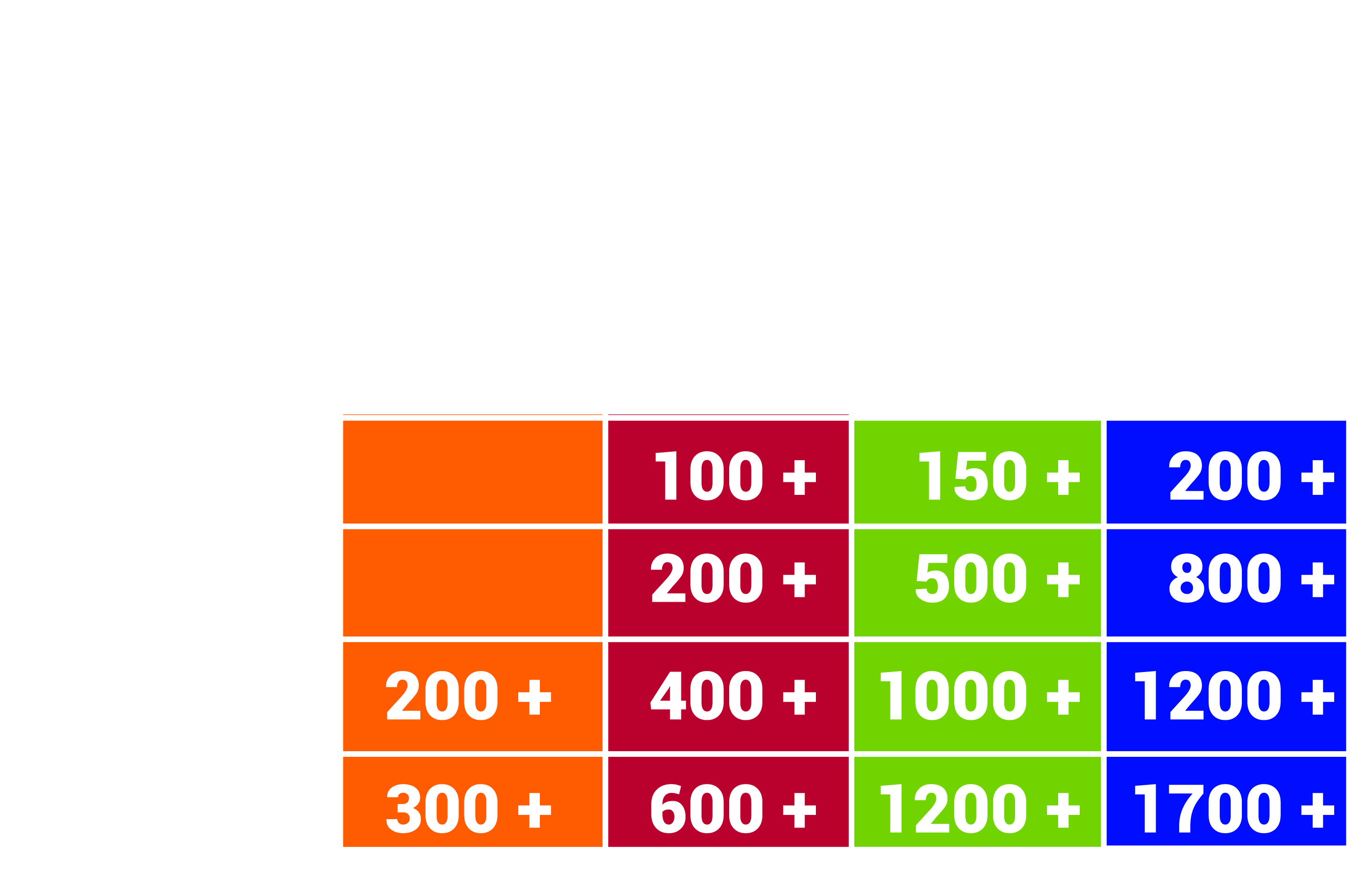

Adaptability to

challenging climatic,

geographical and

geological conditions.

Adaptability to challenging climatic, geographical and geological conditions.

High production and

excellent depth

capacity.

High production and excellent depth capacity.

Modular components

and standardized

design increase

reliability and

minimize downtime.

Modular components and standardized design increase eliability and minimize downtime.

Easy transport and

assembly of lighweight

components (max.

weight of an individual

component (160 - 180kgs)

Easy transport and assembly of lighweight components (max. weight of an individual component (160 - 180kgs)

Minimal

environmental

impact.

Minimal environmental impact.

Fast and efficient

logistical support.

Fast and efficient ogistical support.